Simulants, Moissanite and Lab-Grown Diamonds.

Simulants, Moissanite and Lab-Grown Diamonds.

Not everything that sparkles is a diamond.

While simulants may flash and dazzle like a diamond, it is important to know that they are not diamonds. Common simulants are often created with glass, moissanite and cubic zirconia (CZ). They are completely unrelated to diamonds at the atomic level and are easily identifiable by their optical and physical characteristics.

Every GIA report scientifically tests each stone to make sure that it is in fact a diamond.

Purchasing a simulant can be a great option as long as it is an informed decision.

Natural appearance, laboratory origin.

Natural diamonds are famous for their age, forming millions to billions of years ago. In contrast, laboratory-grown diamonds are young. With a variety of high-quality options in new colors at a reduced price point, the demand for laboratory-grown diamonds has risen in recent years.

Like their natural counterparts, laboratory-grown diamonds have the same crystal structure, consisting of tightly bonded carbon atoms. This results in nearly the same chemical, optical and physical properties as natural diamonds. By eye, the difference can potentially be indistinguishable. However, they are separated by vastly different growth histories, which experienced gemological laboratories like GIA can detect with advanced instrumentation.

Natural appearance, laboratory origin.

Natural diamonds are famous for their age, forming millions to billions of years ago. In contrast, laboratory-grown diamonds are young. With a variety of high-quality options in new colors at a reduced price point, the demand for laboratory-grown diamonds has risen in recent years.

Like their natural counterparts, laboratory-grown diamonds have the same crystal structure, consisting of tightly bonded carbon atoms. This results in nearly the same chemical, optical and physical properties as natural diamonds. By eye, the difference can potentially be indistinguishable. However, they are separated by vastly different growth histories, which experienced gemological laboratories like GIA can detect with advanced instrumentation.

(Octahedron) Sir Oppenheimer Student Collection, (HPHT & CVD) GIA Research Collection.

The history of laboratory-grown diamonds.

1950s: Union Carbide produces the first Chemical Vapor Deposition (CVD) diamonds in 1952. Others, including General Electric, produce diamonds using the high-pressure, high-temperature (HPHT) method soon after. These diamonds were used for a range of industrial and technological applications.

1970s: General Electric researchers create the first gem-quality laboratory-grown diamonds. They are of high enough clarity and large enough size to be suitable for jewelry. GIA scientists publish the first scientific study of laboratory-grown diamonds in 1971.

Mid-1980s: Manufacturers grow commercial quantities of gem-quality laboratory-grown diamond crystals. These lab-created diamonds are initially mostly small and yellowish or brownish in color, but their quality improves over the ensuing decades.

2000s: Gem-quality diamonds are created using the chemical vapor deposition (CVD) method, which requires lower pressures and temperatures than the HPHT method.

Mid-2010s: Colorless laboratory-grown diamonds are available in the jewelry market in commercial quantities. Both HPHT and CVD continue to be popular methods of laboratory-grown diamond production.

Making a diamond.

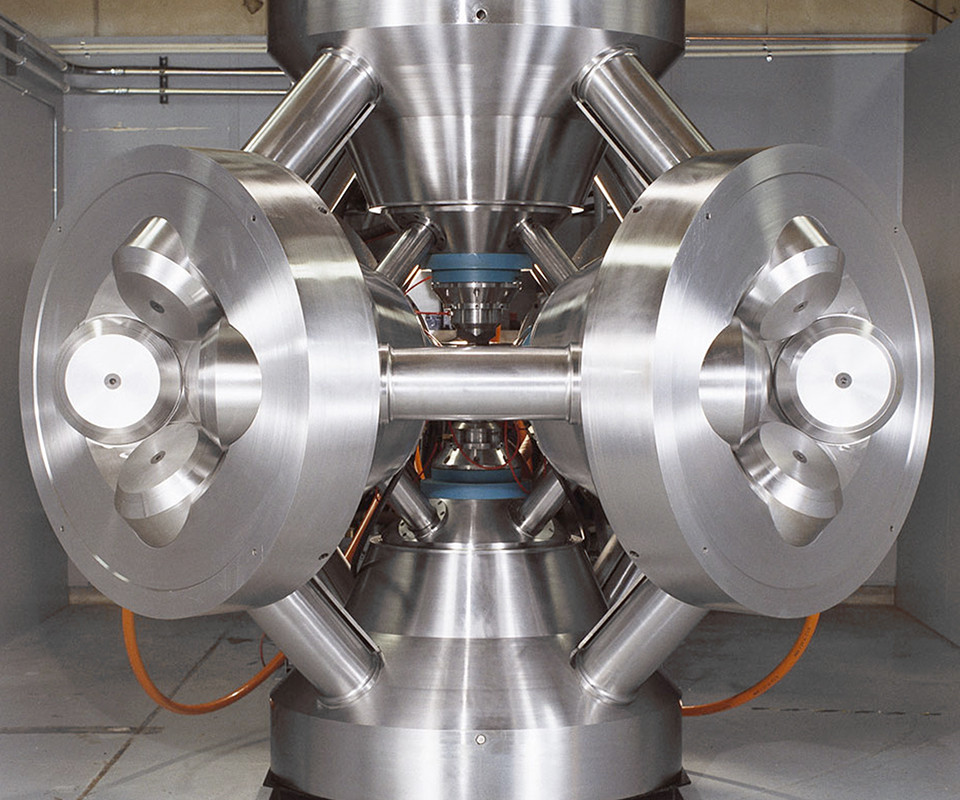

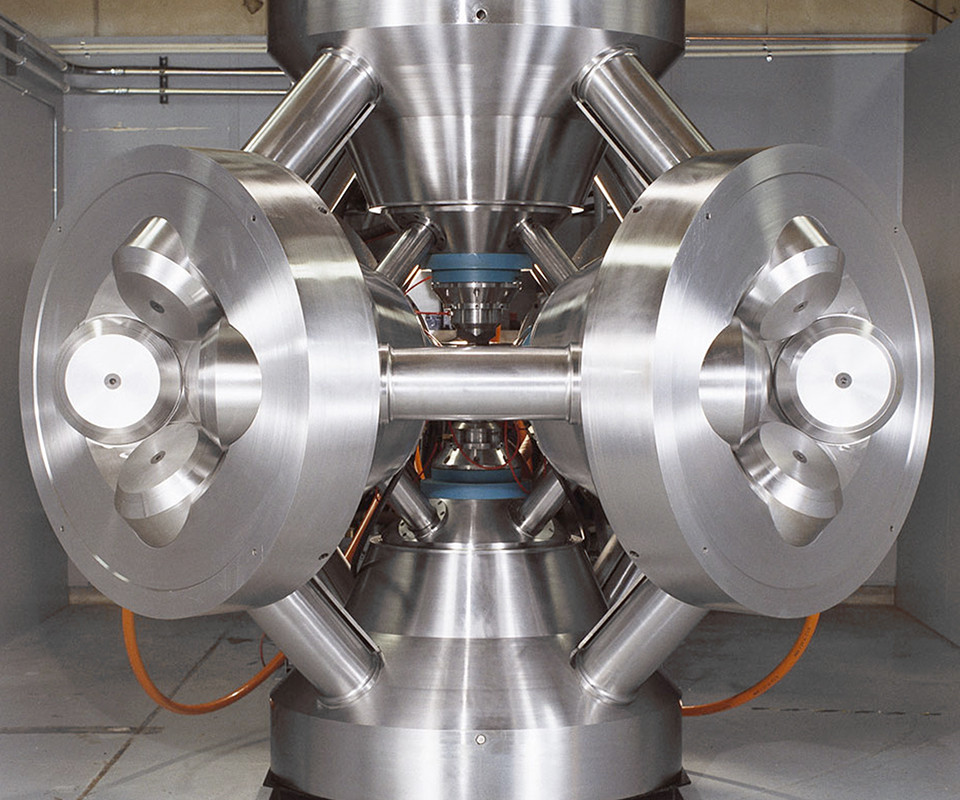

There are two main processes used to create laboratory-grown diamonds: High-Pressure, High-Temperature and Chemical Vapor Deposition.

High-Pressure, High-Temperature (HPHT): Mimicking some of the key conditions of diamond formation – a capsule containing a source of carbon and a mixture of metals is heated to temperatures of 1300-1600°C (2400-2900° F) under pressures of 5-6 GPa, the equivalent of a depth of 150-190 km (~90-120 miles) beneath the surface of the Earth. An HPHT press can also be used to treat diamond color. The size of the diamond depends on several parameters, including the time allowed for growth and the volume of the capsule.

Chemical Vapor Deposition: Dramatically different from natural growth, CVD occurs at near-vacuum pressure. Based on complex gas-phase chemical processes typically activated by microwaves, the resulting glowing plasma ball releases carbon-containing constituents that rain onto diamond seeds, crystallizing as a new diamond at temperatures of 700-1200 °C (~1300-2200 F). CVD growth ideally progresses layer-by-layer, with each subsequent layer replicating the crystal structure beneath, creating a cubic block of diamond. The eventual size of the diamond depends on the size of the diamond seeds and the time allowed for growth.

Making a diamond.

There are two main processes used to create laboratory-grown diamonds: High-Pressure, High-Temperature and Chemical Vapor Deposition.

High-Pressure, High-Temperature (HPHT): Mimicking some of the key conditions of diamond formation – a capsule containing a source of carbon and a mixture of metals is heated to temperatures of 1300-1600°C (2400-2900° F) under pressures of 5-6 GPa, the equivalent of a depth of 150-190 km (~90-120 miles) beneath the surface of the Earth. An HPHT press can also be used to treat diamond color. The size of the diamond depends on several parameters, including the time allowed for growth and the volume of the capsule.

Chemical Vapor Deposition: Dramatically different from natural growth, CVD occurs at near-vacuum pressure. Based on complex gas-phase chemical processes typically activated by microwaves, the resulting glowing plasma ball releases carbon-containing constituents that rain onto diamond seeds, crystallizing as a new diamond at temperatures of 700-1200 °C (~1300-2200 F). CVD growth ideally progresses layer-by-layer, with each subsequent layer replicating the crystal structure beneath, creating a cubic block of diamond. The eventual size of the diamond depends on the size of the diamond seeds and the time allowed for growth.

Identifying a laboratory-grown diamond.

Laboratory-grown and natural diamonds fundamentally differ in the way that the crystal was produced and the environment that they were exposed to since growth, resulting in clues that we can use to separate them. The species, distributions and relative concentrations of small atomic-level irregularities in the crystal and impurities, scientifically known as defects, reveal whether a diamond is natural or lab-grown. Specially developed screening equipment and advanced testing at gemological laboratories like GIA exploit these differences and ensure that the two materials can be confidently separated.

We’ve conducted research on laboratory-grown diamonds since their advent. We use a combination of advanced gemological and spectroscopic techniques to identify laboratory-grown diamonds.

Identifying a laboratory-grown diamond.

Laboratory-grown and natural diamonds fundamentally differ in the way that the crystal was produced and the environment that they were exposed to since growth, resulting in clues that we can use to separate them. The species, distributions and relative concentrations of small atomic-level irregularities in the crystal and impurities, scientifically known as defects, reveal whether a diamond is natural or lab-grown. Specially developed screening equipment and advanced testing at gemological laboratories like GIA exploit these differences and ensure that the two materials can be confidently separated.

We’ve conducted research on laboratory-grown diamonds since their advent. We use a combination of advanced gemological and spectroscopic techniques to identify laboratory-grown diamonds.

The GIA iD100® distinguishes natural diamonds from laboratory-grown diamonds.

Innovations in instrumentation.

Laboratory-grown diamonds can also be sent to gemological laboratories like GIA for identification.

Unbiased evaluation for every diamond.

We examine every diamond to determine if it is natural, treated or laboratory-grown. Our graders evaluate each laboratory-grown diamond with the same expertise and precision as natural diamonds. Our GIA Laboratory-Grown Diamond Report provides detailed color and clarity specifications as well as a plot of the stone’s clarity characteristics.

We are able to scientifically determine whether a diamond was grown through HPHT or CVD using spectroscopy and other testing methods. Diamond treatments can also be used to enhance laboratory-grown diamonds. The Laboratory-Grown Diamond Report also states whether there is evidence of any post-growth treatments.

As an added precaution to protect consumers, GIA laser-inscribes each laboratory-grown diamond’s girdle with the report number and a statement identifying it as laboratory-grown.

Unbiased evaluation for every diamond.

We examine every diamond to determine if it is natural, treated or laboratory-grown. Our graders evaluate each laboratory-grown diamond with the same expertise and precision as natural diamonds. Our GIA Laboratory-Grown Diamond Report provides detailed color and clarity specifications as well as a plot of the stone’s clarity characteristics.

We are able to scientifically determine whether a diamond was grown through HPHT or CVD using spectroscopy and other testing methods. Diamond treatments can also be used to enhance laboratory-grown diamonds. The Laboratory-Grown Diamond Report also states whether there is evidence of any post-growth treatments.

As an added precaution to protect consumers, GIA laser-inscribes each laboratory-grown diamond’s girdle with the report number and a statement identifying it as laboratory-grown.

Expertise at your fingertips.

You don’t need to be a gemologist to purchase a diamond with confidence. You just need to know where to find one.

GIA is the trusted benchmark for diamond grading. Download the GIA App now to learn more about the 4Cs and look up GIA reports.

Expertise at your fingertips.

You don’t need to be a gemologist to purchase a diamond with confidence. You just need to know where to find one.

GIA is the trusted benchmark for diamond grading. Download the GIA App now to learn more about the 4Cs and look up GIA reports.

Expertise at your

fingertips.

You don’t need to be a gemologist to purchase a diamond with confidence. You just need to know where to find one.

GIA is the trusted benchmark for diamond grading. Download the GIA App now to learn more about the 4Cs and look up GIA reports.

GIA Report Check

Access your GIA Grading Report results using your GIA report number.